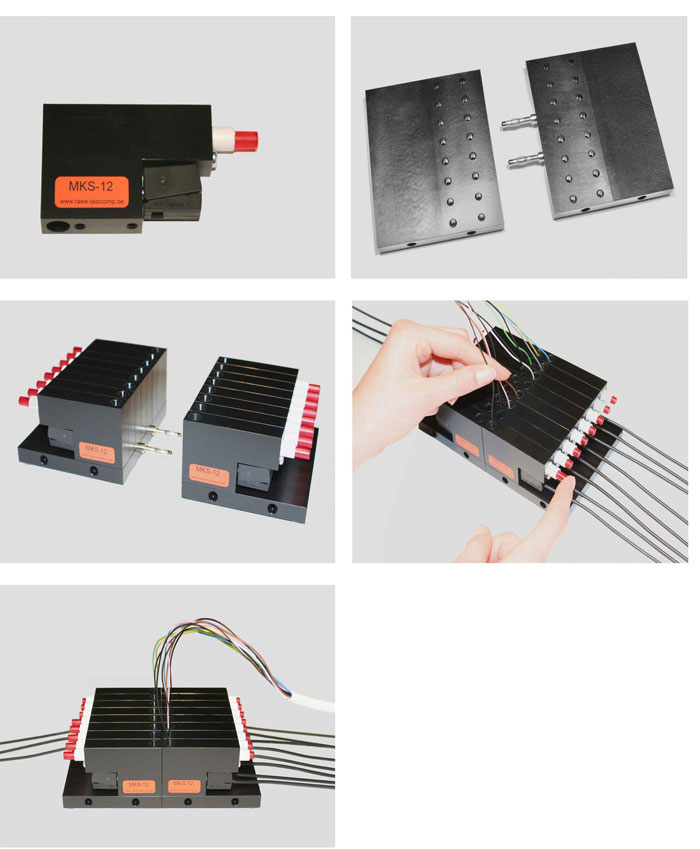

8.1 Mechanical bonding series MKS-12

Economic and innovative solutions for bonding single lines for test purposes.

Mechanical bonding for development, laboratory, test room.

– Housing and control elements made of plastic

– Open and close the bonding by finger pressure

– Easy introducing of the line using an insertion funnel

– Clamping hole diameter 2.8 mm for lines up to 1.5 mm²

– High power rating

– Low contact resistance typ. <10mOhm / 5V/1Amp.

– Electr. connection using quick-action laboratory plug

– Arrangement in rows on the carrier plate with 12 mm grid size

8.2 Mechanical bonding series MKS-12. For strands or wires, with bare or tinned ends, pin contacts, wire end sleeves or other mounting parts.

Bonding modules for fast and safe electrical bonding of single lines in test facility development

and small batch production.

Technical features

– The cable clamp safely locks in the two positions “open” and close.

The clamp closes by finger pressure on the actuating button and opens again by pressing again.

– Insertion of the line is made easier by an insertion funnel above the clamping area.

If the MKS-12 is turned by 90° and mounted, the line can be inserted horizontally.

– Housing, insertion funnel and control elements are isolated and made of plastic.

Dimensions: L = 60 mm + actuating button, H = 38 mm, W = 12 mm, construction grid.

– Clamping hole diameter 2.8 mm to accommodate conductor cross sections from

AWG25 / 0.14 mm² up to AWG15 / 1.5 mm² with a stripped length starting from 5 mm.

– High power rating due to a large contact surface, low contact resistance,

typically lower than 10 mOhm at 5V / 1A.

– Connection is made with standard laboratory cables to a 4 mm socket, a quick-action

laboratory plug is supplied for connecting wires without connector.

– The MKS-12 is connected with 2 of the supplied threaded screws from below through

the base plate, the easiest way is to use the carrier plate described below.

Accessories

Extensible carrier plate type MKS-TP8

For accommodating 1 to 8 bonding modules MKS-12.

– For easy and safe mounting of the bonding modules in grid size 12 mm.

– The TP8 carrier plate is equipped with rubber feet and provides safe positioning

of the bondings.

– The carrier plates made of robust plastic are extensible as desired using system

connectors. 2 connectors are included in the scope of supply.

– The carrier plates can also be connected laterally reversed to obtain two clamping

hole rows with only 12 mm spacing.

– If the conductors have to be inserted horizontally, the complete unit can also be

turned by 90° and operated. A hole of 4.2 mm is provided in the carrier plate for wall mounting.

– External dimensions: D = 80 mm, W = 8 x grid 12 mm = 90 mm, H = 10 mm.

Note

For connecting and operating the MKS-12, please observe the relevant rules and

regulations of electrical engineering.

Order data

Order No.:

MKS-12 bonding module

MKS-TP8 carrier plate

8.3 Mechanical bonding series MKS-12

Replacing the latch mechanism

– For disassembly, place the MKS upright with the latch upwards.

– Remove the clamping screws as well as the actuating sleeve, the actuating

nipple and the latch (do not remove the spring or the contact rod!).

– Now place the actuating nipple above the spring (opening towards the spring)

and slide the new actuating latch over the nipple.

– Slide the new actuating sleeve into the MKS bore, gradually inserting the

contact shaft into the front guide bore of the MKS.

– Carefully insert the actuating sleeve up to the stop - this should be possible

without any pressure – and screw in again the clamping screw up to the collar.